Life Cycle Assessment: 6 areas designers need to consider when taking an LCA approach to vehicle development

A blog by Russ Balzer, Technical Director for WorldAutoSteel and Dr. Don Malen, College of Engineering at the University of Michigan

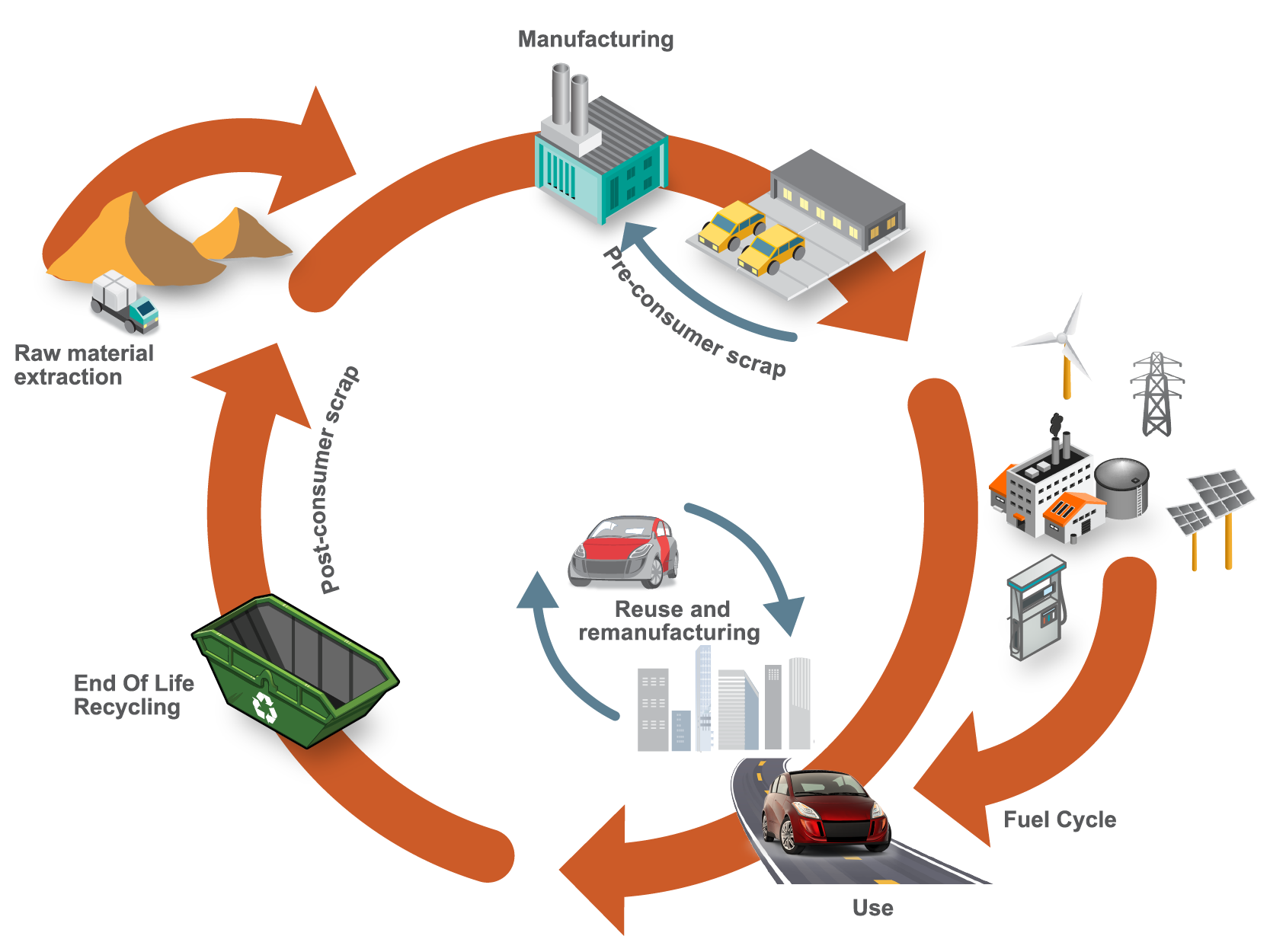

Life Cycle Assessment (LCA) is a methodology that considers a product’s entire life cycle, from raw material and production (manufacturing phase) through its useful life (use phase) to the end-of-life disposal or recycling (end-of-life phase). It also takes into account the full life cycle of its energy sources.

A Life Cycle Assessment approach assists manufacturers in evaluating and reducing the overall environmental impact of products. Steel E-Motive’s engineers are actively incorporating LCA during the development of the concept vehicles to aim for lowest total greenhouse gas (GHG) emissions for these Mobility as a Service (MaaS) vehicle concepts.

Designing vehicles with an Life Cycle Assessment focus is a new concept for most product designers. In this blog, we define six areas for designers to consider when taking an Life Cycle Assessment approach to vehicle development: Functional Equivalence, Material utilization, Material emission impact, Trade-offs between stages, Re-use, Re-manufacture, Recycling, and Matching the LCA tool to the design stage.

The Vehicle Life Cycle

A Life Cycle Assessment considers the environmental impact of a product throughout its total life cycle. The Vehicle Life Cycle is illustrated below.

6 areas for designers to consider when taking an Life Cycle Assessment approach to vehicle development

Functional Equivalence

Make comparisons based on the same function (functional unit).

Material Utilization

Include material utilization (i.e. prompt scrap rates) in evaluating material and manufacturing options.

Material Emissions Impact

Evaluate the emissions associated with each material and its material production method.

Trade-offs

Assess and understand design decision trade-offs over the total life cycle.

Re-use, Re-manufacture, Recycling

Consider the “Three R’s” of product end-of-life when assessing environmental impact.

Match LCA tool to the design stage

Use the appropriate Life Cycle Assessment tools for each stage of the design process.

1. Functional Equivalence

When comparing designs, functional equivalence is an important concept to consider. A critical part of any Life Cycle Assessment study is to define the “functional unit”: The function performed by the part or system being studied. This definition is particularly important when making comparisons.

For example, it would be inappropriate to compare the “body” of a vehicle with a body-on-frame construction to the “body” of a vehicle with unibody construction. Though both systems are casually referred to as the “body”, their functional requirements are very different. Similarly, when comparing an assembly of stamped parts to a single casting, it is important to include all the stamped parts that are required to meet the same functional performance as the cast part. To be useful, comparisons must be made based on the same function or functional unit.

2. Material Utilization

In any production process, there is some degree of waste. When we measure the environmental impact of the materials in a product, we must consider not just the materials that are in the final product, but the total amount of material that had to be produced to achieve the final product. This means we must account for any loss of material along the way, such as prompt scrap generated during part production and the scrapping of defective parts.

Different manufacturing methods, even when applied to the same material, may result in different amounts of waste associated with them. Roll-forming, for example, may generate much less prompt scrap than traditional stamping. Some materials are more susceptible to defects than others and will thus have more parts scrapped than another material, even though the part and the manufacturing process are similar. It is therefore necessary to evaluate material and manufacturing options with this in mind.

3. Material emissions impact

Different materials will have different environmental impacts associated with their production. The same material produced by different methods or at different locations may have different impacts.

For many materials, the energy required to produce them is the largest source of impact. If the production of a material requires a large amount of electricity, how that electricity is generated may to a large extent determine the impact of the material’s production. A specific material can be produced via different production routes having different levels of energy consumption.

It can also be important to consider the size and nature of the material markets as these will affect the type of data available. Some materials are very specialized. For example, they may be produced at only a few places or have only a few applications. In these cases, specific production data might be required. Conversely, other materials are global commodities where demand changes in one sector or location can affect other sectors in other parts of the world. These considerations can determine whether national, regional, or global data should be used.

4. Trade-offs

Taking a life cycle perspective means assessing and understanding trade-offs between the phases of the life cycle. Design choices intended to reduce the impact in one phase, will often have detrimental effects in other phases. Optimizing a product for a single life cycle phase can result in unintended consequences. A good example in the automotive sector is the use of low-density materials to reduce mass thereby decreasing fuel consumption resulting in lowering use phase CO2 emissions. The trade-off in this case is that low-density materials are usually more energy-intensive to produce, which increases the emissions in the production phase. Care must be taken that the use phase savings are not outweighed by increases in the production phase. Understanding trade-offs like this is essential in designing environmentally sound products.

5. Re-use, Re-manufacture, Recycling

For many products, the “Three R’s” are an important consideration when assessing the potential environmental impact. Designers must consider:

- Will the given design affect product recyclability?

- Can the design use recycled material to manufacture the product?

- Will the design enable the product or its parts to be re-usable or re-manufacturable?

End of life, EOL, treatment should be carefully considered to minimize the overall impact and optimize the use of materials.

6. Match Life Cycle Assessment tool to the design stage

The different stages of the design process will determine how and why LCA is applied. Early in the design process, the designer may be more interested in an approximate, high-level application of LCA to determine hot spots, those areas of highest impact, or to compare material options. For this purpose, it may be acceptable to use more generic data (i.e. global or regional average) , and broader assumptions in a “back of the envelope” fashion. As the design becomes more mature, the approach may need to be refined to better optimize for LCA, employing a more formal publicly available LCA calculation tool and using supplier-specific data. As the design reaches maturity the objective is to report formal LCA results. Here, the designer may want to move to a bespoke tool tailored to the product and process sector. The tool will likely incorporate data from the specific suppliers and adhere to standards or guidelines such as ISO14044, the EU Product Environmental footprint.

Life Cycle Assessment is minimizing trade-offs between specification and environmental impact.

Some elements of future vehicle design could reduce environmental impact in some phases of the vehicle’s life cycle, while increasing impacts in other phases. Using Life Cycle Assessment as a framework can help minimize these trade-offs, ensuring that the vehicles designed for this new mobility are really doing their share to reduce transport emissions.

Find out more about how the Steel E-Motive vehicle concepts is developing so far.

Further reading on LCA

Circular Economy Perspectives for the Management of Batteries used in Electric Vehicles

Russ Balzer

Dr. Don Malen

College of Engineering, University of Michigan

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.