Effective future mobility design for manufacture, using Advanced High-Strength Steels

An innovative, affordable, and easy-to-manufacture future vehicle for Mobility as a Service

It takes some imagination to envision a future with a radically different transport system, where people travel in autonomous vehicles in a ride-hailing model. But ridesharing is an important component in the plan to reduce global transport emissions. Developing affordable options, both to the customer and the service provider will affect its uptake. That is the premise for the future mobility solution that the Steel E-Motive project, commissioned by WorldAutoSteel, aims to conceptualise, design and validate. UK-based global engineering and environmental consulting firm Ricardo was commissioned to lead the engineering and design effort on the project.

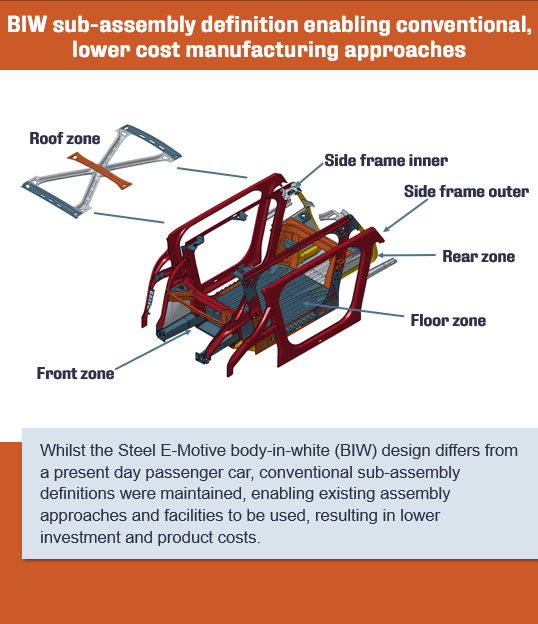

Embedding design for manufacture from the start of the project

Ricardo’s Steel E-Motive Chief Engineer Neil McGregor leads the project engineering team and ensures that all the technical targets are delivered. He said that when engineering a vehicle to be manufactured from Advanced High-Strength Steel, Ricardo knew that the ‘design thinking’ needed to include prioritising cost and efficiency alongside safety and sustainability targets, from the start of the project:

“We ensured that the Steel E-Motive body was engineered to follow conventional high-volume body and vehicle assembly processes, leading to low investment with a lean process and affordable end product. The main efficiencies were achieved by ensuring that this truly innovative vehicle body structure can be assembled using existing production capabilities, removing the need for manufacturers to invest heavily in new equipment and facilities.”

Steel is a versatile material and easy to work with as part of a ‘design for manufacturing’ process. Advanced High-Strength Steel properties can be tailored to solve complex design challenges while achieving the high-strength requirements of a vehicle. These attributes are then leveraged to design for effective manufacturing. Two key production phases benefit from the unique properties of Advanced High-Strength Steels: forming and joining.

Forming Steel E-Motive vehicle body parts using Advanced High-Strength Steel

Selecting the correct materials is a crucial part of the ‘design for manufacture’ thought process; in the case of Steel E-Motive, the Advanced High-Strength Steel grades were chosen to achieve specific vehicle part performance targets and enable their manufacture in all regions of the globe.

Neil McGregor explains that:

“In general, materials that are high strength suffer from poor formability and so as a rule you cannot have both highly formable steel and high strength. With the Steel E-motive body structure we wanted to create some complex shapes and geometry but knew that they would be difficult to press. The solution was to use Advanced High-Strength Steels because their properties allow us to have both high strength and high formability. The exact grade of steel selected is decided by the required strength and shape of the part that you want to make, along with its intended functional requirement.”

As an example, there is a front torque box on the Steel E-Motive vehicle with a complex geometry that challenges formability, but it also needs to be quite strong. The assembly process required welding to an area of the vehicle body through a very steep angle. The project team simplified the design and connection points, to transition from a 3-part stack-up to a 2-part stack-up for more robustness and greater manufacturing quality.

A variety of forming processes have been adopted as part of the Steel E-Motive project. These processes are used efficiently to create the 200-odd individual components that make up the body structure. These include cold stamping, hot stamping, hydroforming, roll forming, roll stamping, tailor-welded blanks and tailor-rolled coils.

Joining Steel E-Motive body parts using Advanced High-Strength Steels

Joining is an essential part of the manufacturing process and was considered early during the Steel E-Motive design phase. In general, Steel is easier to join than alternative materials, presenting fewer challenges when it comes to creating a full body structure from sub-assemblies of various body parts.

Neil McGregor said:

“Joining some of the latest but different Advanced High-Strength Steel grades requires more careful consideration due to varying alloy content, but the Steel E-Motive team has proven through the project that it is possible to solve those challenges.”

Steel’s extensive product and fabrication portfolio enables the design, engineering and manufacturing challenges of mobility as a service vehicles to be solved with little disruption to existing production line processes and requirements. Thus, fully autonomous and connected electric vehicles can be manufactured with ease at an affordable cost across the world, using Advanced High-Strength Steels.

Find out more

Two mobility as service vehicle concepts are being developed as part of the Steel E-Motive project: a 4-passenger variant for inner-city use and a larger 6-passenger extra-urban variant – this will service short journeys such as city-to-airport runs and can also be adapted and used as a delivery vehicle. The vehicles are conceptual and virtual, with no current plans for full-scale production, but the level of validation means a future prototype build is quite feasible, depending on industry interest and feedback.

Steel E-Motive engineering and validation will be completed later this year, at which time the team will share design concepts and results globally. Stay on the Steel E-Motive journey with us as more engineering decisions and solutions will be revealed between now and the end of the year. To stay in touch with webinars, technical publications, and conferences where we will present results information this year and next, as well as learn more about the Steel E-Motive vehicle design progression, be sure to subscribe.

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.

You might also be interested in