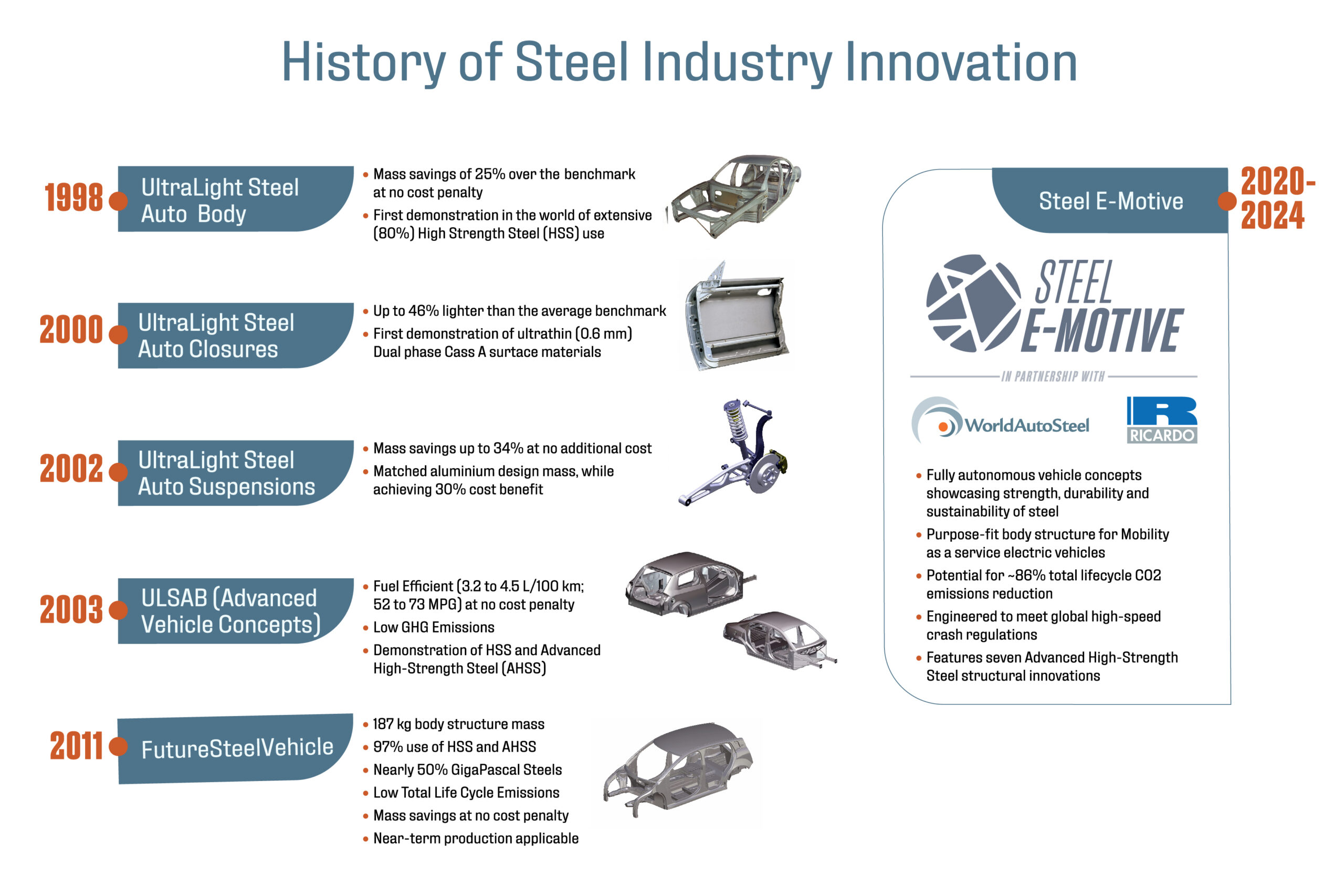

A History of Steel Innovation

Steel E-Motive is the latest in a 26-year history of innovative automotive steel programs

Global steelmakers have a long history of investment in vehicle material application demonstrations to assist the automotive industry in applying steel innovation to current and future vehicles. Steel E-Motive is the sixth program in WorldAutoSteel‘s 26-year history. These programs represent over €100 million in steel industry investment, the engineering and findings of which we make freely available to all.

The research programs have made a dramatic impact on current vehicle architectures. AHSS can be found in nearly every vehicle on the road today in the world, using applications that closely mirror this revolutionary work. The fact that automakers are applying their findings to reach design, engineering and manufacturing goals on a global order of magnitude is evidence of their success in providing viable solutions for vehicle efficiency. We are confident that Steel E-Motive will provide innovations that will have the same exciting effect on the next generation of mobility.

Ultralight Steel Auto Body (ULSAB)

The Ultralight Steel Auto Body program was the first industry collaboration of its kind in the world. It was the first time that High-Strength Steels were demonstrated in unique vehicle applications. The progam demonstrated that steel has the capability to enable a substantial cost-effective weight reduction in the vehicle body structure without compromising safety, comfort or vehicle performance.

The ULSAB program demonstrated impressive mass saving of 25% at no additional cost. The design also demonstrated significant performance improvements, met all mandated crash requirements and maintained affordable manufacturing costs.

Ultralight Steel Auto Closure (ULSAC)

The Ultralight Steel Auto Closure program demonstrated some of first applications of Class A surface Advanced High-Strength Steels (AHSS). This was a lightweighting program which produced designs for doors, hoods, decklids and hatches which were up to 32% lighter. Further weight reductions were achieved by designing steel frameless doors which were up to 46% lighter than the average. All this was achieved whilst maintaining affordability at high-volume manufacture.

Ultralight Steel Auto Body – Advanced Vehicle Concepts (ULSAB-AVC)

The Ultralight Steel Auto Body – Advanced Vehicle Concepts program applied new steels, inovation and advanced manufacturing processes to improve the sustainability and affordability of mid-sized and C-Class vehicles. The new designs improved fuel efficiency, reduced CO2 and was made from 100% recyclable steel, whilst maintaining affordable manufacturing costs. The program demonstrated that steel is an affordable and sustainable material option for vehicles of the future.

Ultralight Steel Auto Suspension (ULSAS)

The Ultralight Steel Auto Suspension program explored the use of steel in the design of automotive suspensions to reduce weight without compromising on cost or performance. A number of designs were created which achieved mass savings of up to 34% whilst achieving a cost benefit of 30%. They are were also manufacturable in high volume at no extra cost.

FutureSteelVehicle (FSV)

The FutureSteelVehicle program demonstrated a vehicle design which used 95% Advanced High Strength Steel to show the potentional of the materials in an automotive context. A mass saving of 39% was achieved as well as showing that AHSS and other steel technologies show the potential for optimized, cost-effective, and sustainable mobility solutions.

Learn more about WorldAutoSteel programs in more detail: https://www.worldautosteel.org/projects/

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.