Media Library

Steel E-Motive Media Centre

Find video, webinar and image updates from the Steel E-Motive program.

For media enquiries contact us at steel@worldautosteel.org

Overview & Q&A

Steel E-Motive media backgrounder

Our two-page media backgrounder provides an overview of the Steel E-Motive project, upcoming key dates and milestones, and spokesperson biographies.

Steel E-Motive Q&A

This extensive Q&A document provides answers to the most frequently asked questions about the Steel E-Motive project.

Technical presentation: Vehicle Architectures for Autonomous Ride Sharing EVs

Learn more about the design and development of the Steel E-Motive autonomous vehicle concepts.

Video Gallery

Steel E-Motive: a sustainable solution for future mobility

This video can be downloaded from YouTube. For decades, steel has been the traditional material of choice for automotive applications and it now can be the sustainable option for future mobility. This is best demonstrated by WorldAutoSteel’s Steel E-Motive programme, which has developed one of the world’s first fully autonomous, battery electric vehicle body structure concepts for ride sharing, that fully comply with global high-speed crash standards. Steel E-Motive is the culmination of a three-year research programme led by WorldAutoSteel in partnership with global engineering firm Ricardo. Since programme results were highlighted in August, there has been considerable interest in its transformative sustainability capability, especially its potential to reduce total lifecycle greenhouse gas (GHG) emissions by up to 86%. This video describes Steel E-Motive’s key features.

The Making of a Scale 3D Prototype

This video can be downloaded from YouTube. Steel E-Motive is a project of WorldAutoSteel to demonstrate Advanced High-Strength Steels and the latest steel frabrication processes applied to Level 5 autonomous electric ride sharing vehicles. Ten 1/3- and 1/4-scale 3D laser printed prototypes were manufactured and hand painted to give engineers a chance to look at the structure in physical form. Manufacturers Hot Buttered Elves in California and George Coates, Technical Director, WorldAutoSteel, in charge of the development program give you a tour and description of how these models are printed and then painted.

Revealed: Steel E-Motive autonomous vehicle design features – B-Roll for media use

This video can be downloaded from YouTube. Results of a global steel industry initiative aimed at developing the world’s first fully autonomous, electric vehicle body structure concept for ride sharing were unveiled today, highlighting key sustainability and performance achievements. The project, called Steel E-Motive, is the culmination of a three-year research program led by WorldAutoSteel and in partnership with global engineering firm Ricardo. Its objective was to create a fully autonomous ride sharing vehicle concept showcasing the strength and durability of steel with a critical focus on sustainability for reaching net zero emissions targets. The results are safe, comfortable, and affordable body structures that support automakers in the continued development of Mobility as a Service (MaaS) ride sharing models.

Steel Innovations that make lightweighting history

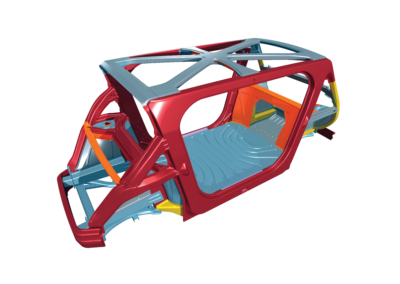

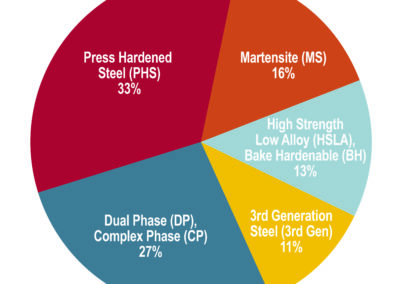

Weighing in at just 282 kg, Steel E-Motive uses the newest steel grades and fabrication processes, which enable tailoring of vehicle properties that achieve significant safety, cost, and comfort advantages with seven key innovations only possible using steel:

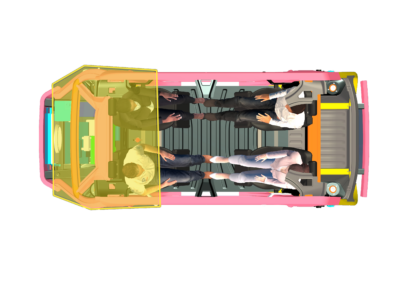

- B-Pillarless, one-box open body structure provides a wider door aperture for easy ingress/egress, disabilities access, and facilitates delivery services.

- AHSS Extended Passenger Protection Zone provides excellent intrusion protection for rear-facing passengers.

- Short Front Crash Zone structure meets the most stringent global crash requirements. Dual Phase (DP) Tailor Welded Blanks enable efficient design.

- Small Offset Crash Glance Beam minimizes cabin intrusion and lowers crash pulse while preserving door ring and battery in 64 kph small overlap rigid barrier simulations.

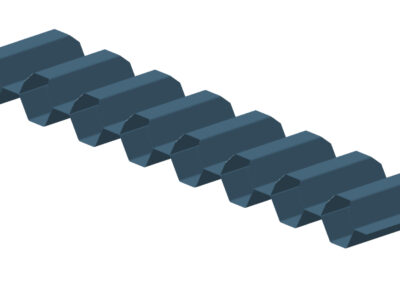

- (Rocker) Hex beam energy absorbers, made of roll-formed DP steel, are low cost, compact, and mass efficient, minimizing side crash intrusion and achieving superior battery protection.

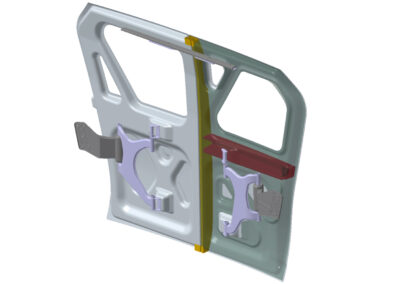

- Virtual B-Pillars are integrated into the doors, creating a compact section for better passenger visibility and improving passenger access. Bake Hardenable steel’s Class A-quality surface combined with a scissor door design enables complete elimination of the body side outer for mass and cost savings.

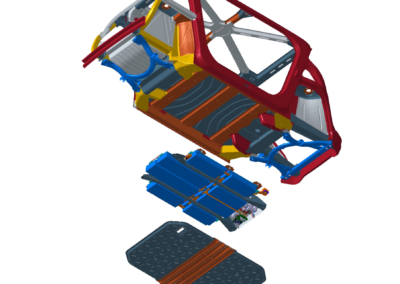

- Industry-First Battery Carrier Frame eliminates the conventional battery case, utilizing the existing floor as the top cover, and features an AHSS triple-skinned bottom cover that seals the battery and provides protection from road debris and jacking errors. These efficiencies result in 37% mass savings (-27% less cost) and can be assembled offline for efficient vehicle integration.

“Steel E-Motive serves as a foundational blueprint for a wide range of applications. Startups and vehicle manufacturers can benefit from fully engineered concepts that can significantly reduce both cost and time to market. It also provides demonstrated results that meet or exceed stringent global crashworthiness standards enabled by the use of high-strength steels – applicable on BEVs in the near-term or future,” explained George Coates, Technical Director, WorldAutoSteel. “From a cost perspective, the study highlights important benefits as well. We engineered this program to be affordable for production and to achieve the lowest total lifecycle emissions, putting us squarely on the path towards Net Zero. Using steel supports the use of existing manufacturing infrastructures, which helps to provide low ownership costs, critical for broad adoption.” Read the press release for more details. Or for those who want to dig into the details, click the button in this post to get the engineering report.

How we designed our self-driving vehicle

Our engineers discuss the reasoning behind some of the design decisions for the self-driving Steel E-Motive vehicle. Vehicle autonomy offers new opportunities to tailor the vehicle to make it more sustainable, accessible, safe, and affordable.

Webinars

This link will navigate you away from steelemotive.world

Mobex – Steel E-Motive: vehicle structures for autonomous mobility as a service

In this free webinar, Neil McGregor of Ricardo and WorldAutoSteel’s George Coates showcase the vehicle technical specifications and expectations for steel innovations. The experts will also outline innovations in the progression of key component structures.

Key topics and takeaways:

- Overview of market influencers and motivations for fully autonomous MaaS vehicles

- Discussion on steel technologies and fabrication processes for future vehicles

- Design challenges and considerations for fully autonomous vehicles

- Development of Steel E-Motive body structure for autonomous MaaS vehicles

- Novel battery enclosure structure giving cost, weight and greenhouse gas benefits

Image Gallery

Please source WorldAutoSteel on any image use.

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.