Designing future autonomous vehicles for use in a ‘mobility as a service’ model

Transport and the way people use it is changing. In the next 20-years, urban mobility is expected to be transformed by the widespread roll-out of fully autonomous vehicles operating within a ride-hailing, mobility as a service (MaaS) model. This will enable people living in and visiting cities to plan, book, and pay for multiple types of mobility services through a digital channel.

This new model could enhance our experience of taking a journey. We will be safer, more comfortable and enjoy a higher level of convenience. Our concern about the cost of the daily commute may also become outdated, as there are also great cost savings to be made both for transport providers and users.

As part of this shift, fully autonomous vehicles operating under a MaaS model have the potential to solve some of the biggest transport challenges that the world faces, namely, the environmental impacts of road vehicles such as reducing road traffic congestion and accidents, greenhouse gases and pollutants, and providing solutions for people who currently have limited access to transport. These solutions will be realised when MaaS is integrated with existing modes of public transport like trains and busses. If we all move towards private ride hailing services (one autonomous vehicle per person, per journey) the problem will not be solved.

Advanced High-Strength Steels will enable future transportation challenges

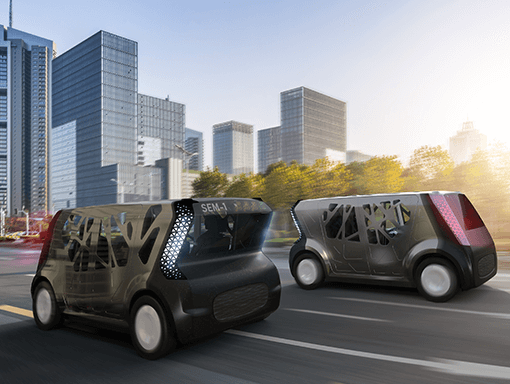

The Steel E-Motive project is a collaboration between WorldAutoSteel and Ricardo, which demonstrates the suitability of the latest Advanced High-Strength Steel grades for use in a fully autonomous vehicle, engineered for a MaaS transport model. We are working together to develop two vehicle concepts; the smaller four passenger “SEM1” variant is intended for inner-city journeys and the larger six passenger variant (SEM2) intended for longer inter-city journeys.

Autonomous vehicles of the future will require many new innovations. This includes development in electrical and control systems in the form of radar and lidar sensors and changes in vehicle architecture or structure. Autonomous vehicles create opportunities and present different requirements, and the structure of vehicles will need to adapt to that.

The Steel E-Motive program is woking to develop two vehicle concepts for MaaS applications.

Addressing population growth and demand for transportation

Autonomous vehicles operating in a ride sharing MaaS model alongside other public transport will help to meet the challenge of serving a growing global population, while providing a sustainable transport solution around and between cities. With ride sharing, the number of single-passenger vehicles on the road drops, reducing traffic congestion, leading to an increase in capacity for passenger numbers and journeys.

This will be important as the global population is forecast to increase by 25% to 9.7 billion in 2050, with a considerable proportion of this growth expected to be in urban and suburban regions.

Both the smaller SEM1 and larger SEM2 Steel E-Motive vehicles are engineered to be compliant with global legislation, specifications, and requirements. This means that they can be used in any city environment.

Addressing the environmental transport challenges in future towns and cities

As cities and suburban areas become more heavily populated, there will be a growing need to move people more efficiently and safely, while supplying sustainable solutions. Being able to hail a ride in an electric autonomous vehicle and share that with others, will help to reduce traffic congestion and reduce carbon emissions and other pollutants.

The Steel E-Motive SEM1 and SEM2 vehicles are ‘all electric’ with zero tailpipe emissions that will help cut urban pollution. The vehicle has been designed to be as environmentally friendly as possible during its complete lifecycle. The aim is that the electricity source used for charging will be provided from an energy mix that is largely renewable (e.g., wind, solar). This will reduce the greenhouse gas emissions generated during the vehicle’s lifetime on the road.

The body structure designs of the Steel E-Motive vehicles also have been engineered to minimise greenhouse gas emissions created during vehicle manufacture. Steel is made in a more environmentally friendly way than many other materials, with fewer greenhouse gas emissions. The Steel E-Motive vehicles incorporate some of the latest “reduced carbon” steel grades in their design and through advanced fabrication processes, achieve more efficient steel use per part, meaning less overall steel production.

Addressing vehicle safety

The future of transport will be safer than it is now. Governments, city planners, vehicle manufacturers and fleet operators already face a big challenge when it comes to reducing accidents for passengers and pedestrians and improving vehicle safety.

Autonomous vehicles operating in a MaaS model can help reduce road traffic accidents and fatalities because the vehicles have advanced sensor and control features that detect potential collisions and rapidly activate avoidance measures reducing accidents caused by human error. However, in the early stages of roll out, these vehicles are expected to operate in a ‘mixed mode’, where autonomous vehicles will be operating alongside owner-driven vehicles. This means that there is still a risk of high-speed vehicle to vehicle or vehicle-to-obstacle collision. To address this, the Steel E-Motive vehicles are engineered to meet high-speed international crash test standards. Leveraging the steel industry’s Advanced High-Strength Steel portfolio, our vehicles are engineered to the demands of MaaS, meet stringent vehicle safety targets, and deliver optimal mass, cost and comfort.

The Steel E-Motive vehicle is designed to reduce road traffic accidents and fatalities

Addressing passengers’ needs

As with all forms of transport people will only want to use autonomous vehicles operating in a MaaS model if the solution addresses their needs. The Steel E-motive vehicle designs ensure that the product and service offering is attractive for people, spurring their interest to travel in this way. These vehicles are designed to be mass produced at high volume and to be affordable. A steel body structure can be produced at a more competitive cost than alternative materials. Autonomous vehicles will also be cheaper to run due to higher operational efficiency in use and reduced labour costs.

The Steel E-Motive vehicles have been engineered with future users’ needs in mind. The Advanced High-Strength Steel body structure is designed to reduce noise and vibration, so that the journey is more comfortable. The vehicles are perfect for ride hailing in an urban environment as they have a flat interior floor, an accessible ‘step-in height’ and a wide entry door aperture. Both vehicles feature four-wheel steering, with a generous turning circle, enabling the vehicles to operate in confined spaces. This makes it easier for people to hail and access the vehicles in restricted areas. Awareness of safety and environmental challenges is on the rise and the design and features of the Steel E-Motive vehicles will reassure future passengers that travelling in this way is contributing to the global drive for safer and sustainable mobility.

Learn more about the Steel E-Motive vehicle design.

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.

You might also be interested in