Balancing openness and accessibility to create a safe and strong autonomous vehicle

Future solutions, free of current constraints

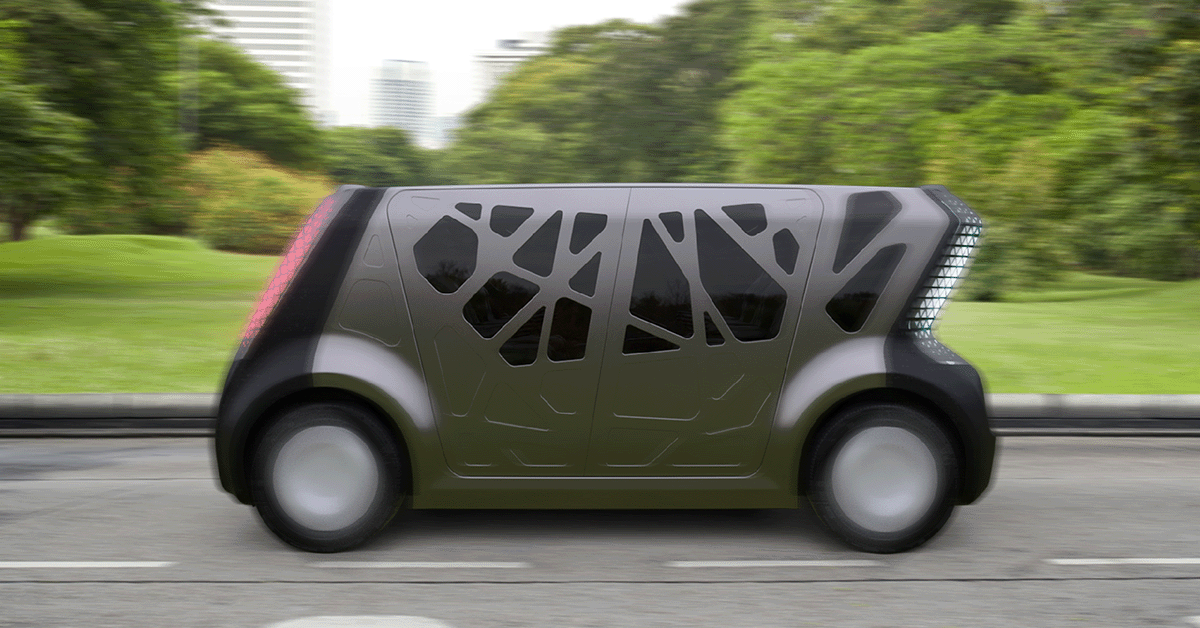

The Steel E-Motive project has moved away from some aspects of traditional vehicle design because the vehicles are autonomous and need to be designed for a diverse range of users and uses. The two vehicle concepts; the smaller four passenger “SEM1” variant is intended for inner-city journeys and the larger six passenger variant (SEM2) for longer inter-city journeys. Using Advanced High-Strength Steels has enabled a more open and accessible vehicle design than those that we see on the road today, without compromising safety. One of the main ways that this has been achieved is through careful design of the closures on the vehicles and the use of Advanced High-Strength Steel.

Designing closures for openness and accessibility

Automotive closures are a critical, structural part of a vehicle and play a very important role in crash performance and add functional value. The design of the doors and trunk for the Steel E-Motive SEM1 and SEM2 vehicles focuses on openness and accessibility, creating an environment that is spacious and accessible, with inward facing seats.

This main design aim posed a challenge because the larger the opening on a vehicle, the harder it is to pass crash safety tests. This was solved by balancing safety with openness and accessibility and positioning the B-pillar, (a vertical pillar in the middle of the passenger compartment) within the door structure. Advanced High-Strength Steel was used to create a stronger, more compact B-pillar allowing more space for glass.

The vehicles have a horizontal sliding ‘scissor’ door system giving access to the cabin and a ‘vertical liftgate’ trunk opening. They are designed to enable ease of use in tight spaces, such as parking nose to tail on the sidewalk and still being able to load luggage.

The Steel E-Motive vehicles have a horizontal sliding door systems which gives access to the cabin.

Critical features with Steel E-Motive closure

Crash safety and anti-theft features

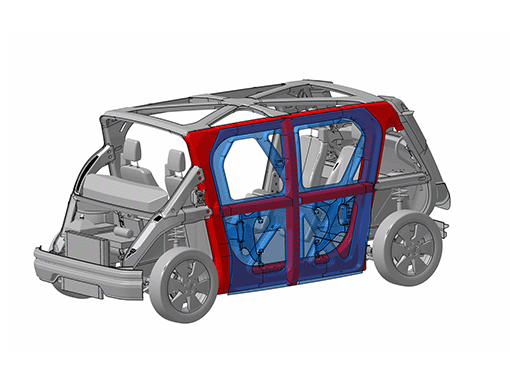

The door beam, essential for intrusion prevention into the cabin in event of a crash, is designed as a horizontal beam inside the door, running from the front to the back of the vehicle. The door interlocks, or anti-theft and break-in features are located around the perimeter of the side door and at the base of the vertical liftgate on the six bar.

When it comes to intrusion prevention, the design differs from conventional cars because the B-pillar is mounted in the door structure, where conventionally it is welded within the body in white. This means that the vehicle does not have a latch and seal interface. The integrated virtual B-pillar is located inside the side door and retains the door beams. It also interfaces with the rocker and cantrail.

The door ring, that runs around the perimeter of the side door and the vertical tailgate, is critical for sealing and helps to control noise, vibration and harshness (NVH).

Design solutions – access and visibility

The hinge system on the side door is called a ‘scissor hinge’ because, when operative, it looks like the movement of scissors. This system is on the inside of the cockpit and is attached to an A-pillar, which straddles the windshield and then to the front side door. It is also attached to a rear C-Pillar, at the rear of the passenger compartment, which in turn is attached to the rear side door.

The door design targets for the kinematics, or movement of the door systems, aimed to make sure that the doors and trunk did not add to the overall length of the vehicle, allowing it to park nose to tail on the sidewalk. To achieve this for the side doors there was a 1m target for opening in a longitudinal direction and a 1200mm target for opening in a vertical direction, in line with the London Transport Taxi Conditions of fitness licensing guidelines.

The curbside overlap when the side doors are open is 250mm ensuring that the vehicle remains inobtrusive and compact in its environment. The Steel E-Motive vehicles can also be configured for goods transportation. The door aperture dimensions will enable a standard ISO pallet to be transported.

Pictured: Steel E-Motive’s AHSS structure for the closure system

Ample glazing is designed into the vehicles and present in the side doors, the front and rear windshield and the roof. This supports the design ethic of openness and accessibility providing light and visibility into and out of the vehicle and enhancing the safety features.

The design features of the Steel E-Motive vehicle closures contribute to vehicle safety, accessibility and openness. The aim is for the improved ride experience that the closures designs supports to make hailing a ride in a future vehicle of this type, an attractive and desirable choice, thus creating value for the mobility service provider.

Do you have questions about Steel E-Motive’s closure designs? Visit our AHSS Insights blog to ask them and/or provide feedback.

Learn more about the Steel E-Motive vehicle design.

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.

You might also be interested in