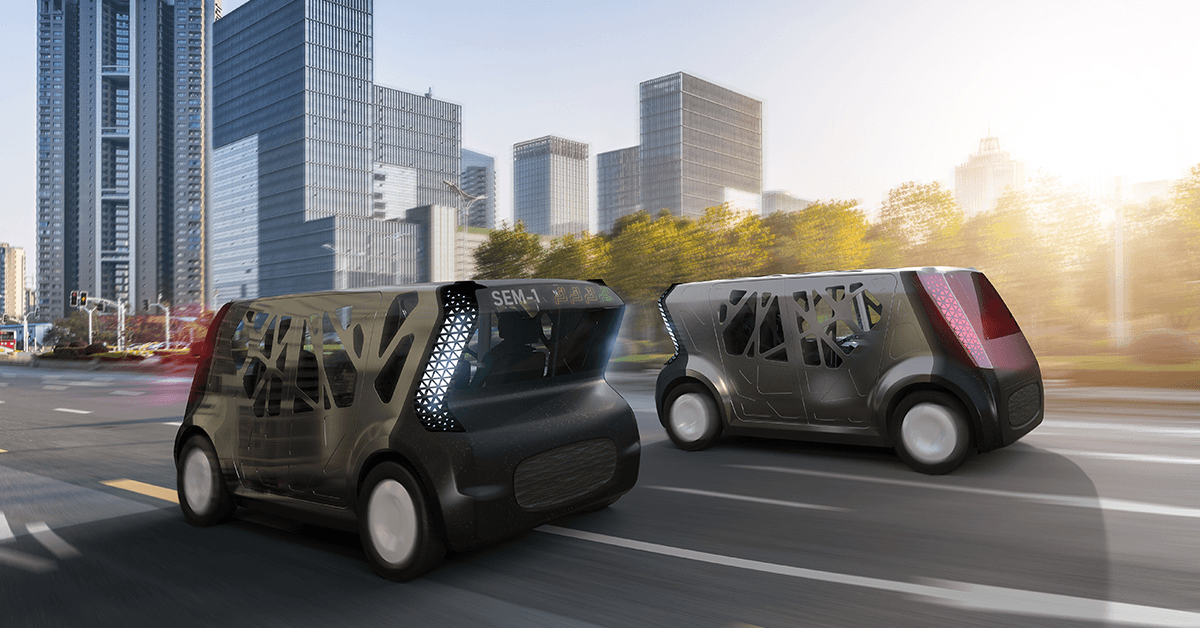

Design unveiled for connected steel autonomous vehicle for future sustainable urban mobility

To advance sustainable transportation by factoring whole lifecycle into a vehicle’s development, WorldAutoSteel and Ricardo have designed a fully autonomous Mobility-as-a-Service (MaaS) steel-enabled vehicle inspired by contemporary urban architecture trends and focused on passenger safety and comfort.

Steel E-Motive, an initiative of WorldAutoSteel, the automotive group of the World Steel Association and its engineering partner Ricardo, a world-class environmental, engineering and strategic consulting company, have unveiled the exterior styling vision for their fully autonomous ride-hailing, ride-sharing vehicle designed to showcase the benefits of using steel for global mobility-as-a-service.

The Steel E-Motive vehicle design has been optimised to include technologies that are deployable by 2030 and beyond and meet requirements for inner-city driving needs. The design concept comprises both a compact, four-passenger vehicle, and a version with space for more passengers and luggage for out-of-town journeys. Designed by Maurizio Tancredi, Chief Style and Industrial Designer at Ricardo, Steel E-Motive’s exterior styling is created around generative design thinking and is inspired by contemporary architecture in global cities, enabling the vehicle to fit harmoniously into the urban landscape.

Cees ten Broek, Director, WorldAutoSteel said: “Since this programme began in November 2020, we have continued to progress with design and engineering of this steel-intensive ride-sharing, ride-hailing vehicle. We’ve focused on delivering a solution that meets the essential requirements for mass scale deployment in future mobility applications. It is efficient in its construction, manufacturing and total lifecycle emissions, as well as attractive in the landscape for which it is intended.”

Using Advanced High-Strength Steel for the design delivers aesthetic, safety, comfort and accessibility benefits. The steel is applied in a pattern that is part of the external visual design rather than being hidden behind outer panels, and the glazing on all sides of the vehicle – including the roof – offers passengers great views of the cityscape. The steel will enable the engineering team to meet mobility-as-a-service operational, safety and environment requirements: for example, its strength and formability supports a unique low-height coverless and integrated battery case, and flat-floor interior – which also aids better accessibility. A unique rocker design offers superior crush force and protection not only to the occupant but the high voltage battery internals. Steel also delivers cost, weight and sustainability benefits over a conventional battery pack using alternative materials, while meeting all current and future anticipated safety standards and legislation. Accessibility is also at the core of the vehicle design. The requirement for low step-in height has driven the primary structure of the vehicle and is enabled by the novel battery case solution. A very wide door opening provides ample access for people and goods, while the unique door structure provides reduced outswing to the roadside.

The Steel E-Motive vehicle design also features battery electric propulsion, Level 5 autonomy and four-wheel steering for maximum functionality and manoeuvrability. The design and engineering reflect likely use in a mixed environment where both manual and autonomous vehicles are operating. Vehicle specifications are geared to high-volume manufacture with vehicle producers, fleet operators and ride-hailing users in mind.

The styling renderings are displayed on Ricardo’s stand 6-230 at the Electric & Hybrid Vehicle Technology Expo in Stuttgart, Germany from 30 November to 2 December 2021.

Subscribe for updates

The Steel E-Motive vehicle concept is still in development. Sign up to be the first to hear about the latest developments from the program.

You might also be interested in