Steel is reducing life cycle emissions of autonomous vehicles

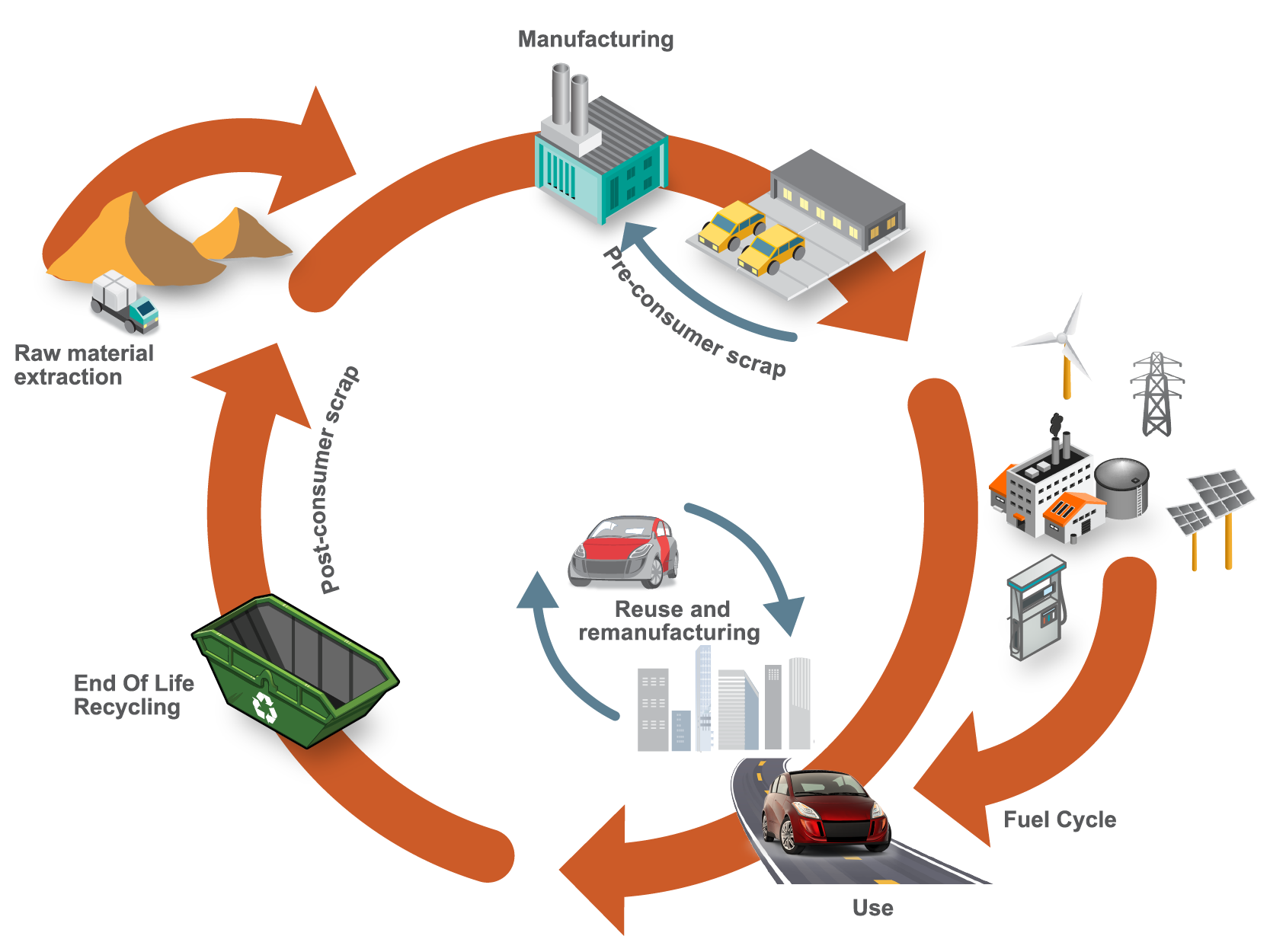

However, it’s not enough to simply look at reducing the operational emissions of these vehicles. Every product has a carbon footprint which spans the entirety of its life, from the production of raw materials right through to end of serviceable life. The Steel E-Motive program is using steel in our autonomous vehicles to make mobility solution which is sustainable across the full product life cycle.

What is a life cycle assessment (LCA)?

A life cycle assessment (LCA) considers all the emissions created during the life of a product, from raw material production to disposal or recycling. LCAs take a holistic view of the environmental impact of a product and make informed decisions about the sustainability of materials, manufacturing techniques and the design of a product. A life cycle assessment for a vehicle covers raw material extraction, manufacturing, use and end of life for the product. It also includes an assessment of the energy source used to power the vehicle.

Steel is reducing the life cycle emissions of the Steel E-Motive vehicle

It is the aim of the Steel E-Motive program to develop a vehicle concept which targets the lowest total greenhouse gas emissions across the product life cycle. The design and engineering team will accomplish this by applying Life Cycle Assessment throughout the concepts’ development. The use of steel in the vehicle concept is helping us to achieve this goal.

Steel has the lowest carbon footprint of any material used in automotive structures. Primary steel production emits 7 to 20 times fewer greenhouse gases compared to other materials. Steel technologies and the methods by which they are manufactured are evolving all the time. The next generation of Advanced High-Strength Steels will continue to reduce emissions impact of production.

Steel production emits 7-20 times fewer greenhouse gases compared to other materials.

The use of Advanced High-Strength Steels also contribute to a reduction of emissions during the operational phase of the vehicle’s life cycle. Using AHSS enables the development of vehicle structures which are strong and durable. This contributes to an extension of useful product life and a reduction in the need for maintenance and repair; all of which contribute to a vehicle’s carbon footprint across its life cycle.

Advanced High-Strength Steels also enable a reduction in the weight of the vehicle without compromising its structural strength. The lighter the vehicle, the less energy is required to operate it. Lightweighting the vehicle will therefore contribute to energy efficiency, meaning that the battery will need to be charged less frequently. Thus, reducing the impact of the energy cycle of the vehicle.

Finally, steel is globally recognized globally for its recyclability and reusability. When the vehicle comes to the end of its serviceable life, the use of steel in the fabrication of the body means that it is easier to repurpose it rather than having to dispose of it. Recycling or reuse of parts of the vehicle structure will reduce the requirement for the extraction of raw materials, further reducing the vehicle’s carbon footprint.

Find out more about Advanced High-Strength Steels

Find out more about LCA for vehicle design

Subscribe for updates

Stay up to date with the latest research and technical updates from WorldAutoSteel

You might also be interested in